The CNC tube bending process is important to the metal fabrication world. It involves bending

metal tubes into precise angles and curves for everything from car parts to furniture frames and

architectural structures. In Canada, technology has come a long way in recent years,

completing projects faster, more precisely, and cheaper.

If you work with metal parts, understanding how brand-new CNC tube bending is transforming

the market will grant you the right fabricator and better results on your projects.

What Is CNC Tube Bending?

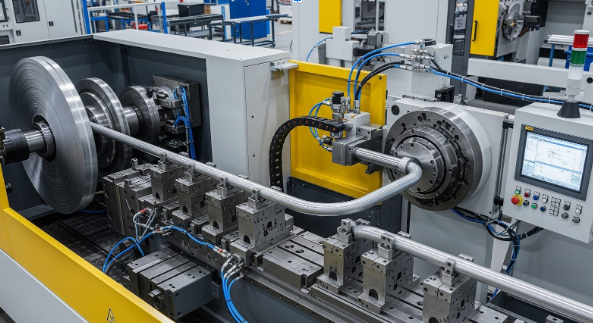

CNC tube bending utilizes computer-driven machines to bend metal tubes according to

computer instructions. The machines are also designed in CAD drawings, which allow them to

bend tubes into complicated shapes again and again with a high level of accuracy and little

room for error.

Applications are varied and range from:

● Automotive exhaust systems

● Structural frameworks

● Furniture as well as railing components

● Heating, ventilation, and air conditioning and plumbing systems

● Aerospace and naval equipment

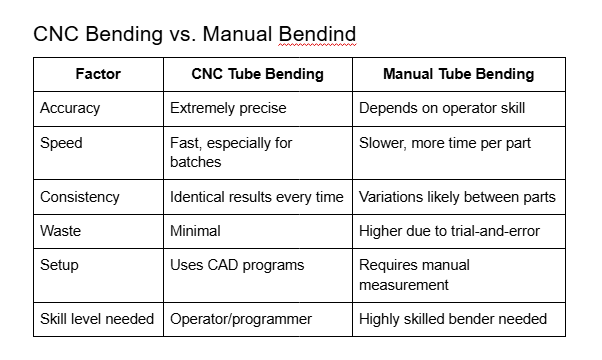

Unlike hand bending, CNC bending is uniform even for high production runs, and it works best for Canadian manufacturers with strict time constraints.

Why CNC Tube Bending Matters

Accurate tube bending matters because slight variances can make components difficult to assemble. CNC machinery decreases much of the experimental nature of traditional methods.

They deliver:

- Accurate, repeatable bends

- Accurate assembly within close tolerances

- Reduced material waste

- Faster turnaround for volume batches

These advantages help Canadian businesses to maintain quality and manage costs of production.

Innovations Driving CNC Tube Bending in Canada

Emerging technology has nudged CNC tube bending beyond mere automation. Canadian fab shops are accepting new technology to improve quality, reduce lead times, and produce more complex designs.

The following are the key advancements redefining the business:

- Real-time simulation software – Allows operators to simulate designs digitally before they are made, reducing errors and material wastage.

- Automatic tool change – The machine can automatically change bending tools, conserving setup time between tasks.

- Integration of measuring system – Sensors within the machine inspect each bend for quality in real-time.

- Multi-axis bending – More recent machines have the capability to bend tubes, a number of axes and planes, producing more complicated designs without welding various pieces together.

- Data monitoring and tracking – Automated monitoring of part quality and bending performance improves quality control and consistency.

These technologies allow Canadian fabricators to make more intricate designs on strict schedules.

Why Canadian Businesses Gain from These Advances

For businesses that depend on metal parts, these developments provide a range of practical benefits:

- Increased production speed – High-speed CNC systems lower lead time and boost throughput.

- Less rework – Less scrap, less rework, and quicker setup save dollars.

- More design freedom – Difficult, complex geometry is simpler to make accurately.

- Improved product quality – Accurate bending secures fits, reinforces joints, and eliminates failure.

- Scalability – Designs programmed once can be replicated for low- or production runs without compromising accuracy.

Canadian businesses can now complete complex jobs at home instead of outsourcing, with more predictable costs and lead times.

When to Apply CNC Tube Bending

CNC tube bending excels when:

- Your application requires accurate dimensions and consistent results

- Medium to high production volumes are required

- Your design has multiple or intricate bends

- Material waste is a priority for reduction

- Post-production work to finish the part needs to be minimized

It is especially useful in applications where accuracy has a direct impact on function or safety, such as in automotive, aerospace, and structural construction.

When Manual Bending Is Still Applicable

Although CNC prevails in most modern jobs, hand bending is still suitable in certain applications:

- Prototyping a single part quickly without having to program

- Very small runs where setup time cannot be justified with automation

- Projects with simple, large-radius bends

- Situation where seasoned craftsmen can make ad-lib changes

These are less common, but they illustrate why some Canadian shops keep hand bending equipment along with their CNC machinery.

Why the Right Fabrication Shop is Important

Not all metal fabrication shops possess the most modern CNC tube bending machines. Choosing a shop that uses the most latest equipment and methods can directly impact your project’s quality, cost, and shipping schedule.

Choose shops that:

- Utilize new CNC bending equipment and computer software

- Offer multi-axis bending for complex parts

- Offer in-shop design support and CAD capabilities

- Apply quality control measures to guarantee accuracy

- Are scalable from prototype runs to production runs

Go visit the shop, ask about equipment, and review previous work and you’ll know pretty well what they are capable of making.

Most Important Points to Think About

- CNC tube bending offers speed, accuracy, and consistency not possible with hand processes.

- New technologies like real-time simulation, multi-axis bending, and tool change automation are transforming the process in Canada.

- The technologies allow businesses to cut costs, increase quality, and manufacture complex designs locally.

- Choosing a shop with premium CNC equipment ensures smoother projects and tighter tolerances.

FAQs

- What materials can be bent using CNC tube bending?

Steel, stainless steel, aluminum, copper, and other metals can be bent to precise specifications by CNC machines.

- Is CNC tube bending suitable for high-volume production runs?

Yes. Programmed and controlled CNC machines can produce thousands of identical pieces affordably.

- How accurate is CNC tube bending?

It can create very close tolerances, typically fractions of a millimetre, for precise fits.

- Is CNC tube bending cost-effective for small orders?

It can be. The setup is quick, so even small runs have consistent quality and minimal scrap.

- What’s the best way to choose the right CNC bending shop?

Look for new equipment, experience with your material type, good client reviews, and good communication.

Conclusion

CNC tube bending is changing Canadian metal fabrication with the use of automation, latest software, and leading-edge machinery. All these are facilitating Canadian businesses to work quicker, accurately, and on more complex projects.

With the technology still developing, if you’re searching for tube bending Canada, partnering with a fabrication shop that embraces these advancements will give your projects the precision, speed, and quality they need to stay competitive.